iinfo re Botanicalsnfo re botanicals —

https://www.madebybarb.com/2023/11/26/how-to-make-eco-prints-on-viscose-or-rayon-bamboo-silk/

https://www.madebybarb.com/2023/11/26/how-to-make-eco-prints-on-viscose-or-rayon-bamboo-silk/

https://acrobat.adobe.com/id/urn:aaid:sc:US:7f9f21d5-8ca9-4599-a2dd-853ae1d0a21f

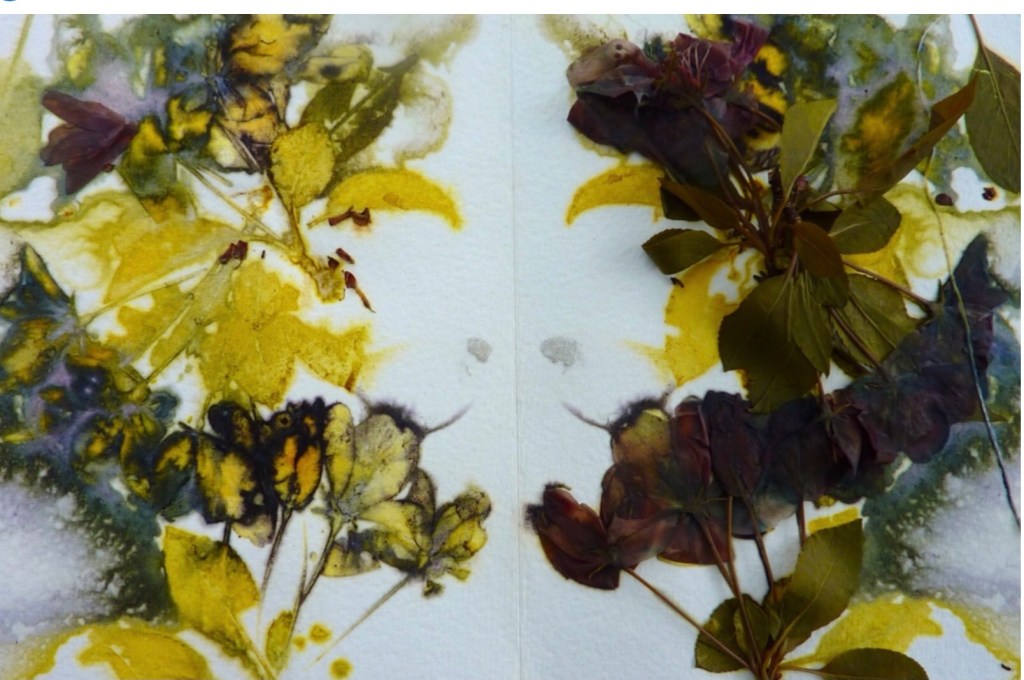

EcoPrinting with Blankets

— MADDER EDITION —

✷ Dye blankets allow you to combine the processes of solid color immersion dyeing fabric or garments & EcoPrinting at the same time!

✷ Using a dye blanket (instead of solid color immersion dyeing the fabric first & then EcoPrinting on top) allows you to create ecoprinted fabrics with vibrant positive prints & undyed ‘negative’ botanical shapes- where the leaves or flowers block the dye.

✷ This technique is unlimited in the possible various outcomes!

✷ Learn how to EcoPrint Socks with this technique too!(Full detailed step-by-step directions included in the Tutorial)

liz@thedogwooddyer.com

https://botanicalcolors.com/mordant-monday-a-rainbow-compilation/

https://search.app/Wj4j7LV2dWbDQ7xr6

https://textiledyegarden.pratt.edu/dye-plant-information/bachelors-button—-bachelor button

https://textiledyegarden.pratt.edu/dye-plant-information/goldenrod —— goldenrod colors

https://textiledyegarden.pratt.edu/dye-plant-information/hopi-sunflower——-=SUNFLOWER COLOURS

https://localcolordyes.com/2011/10/19/dyeing-with-ladys-bedstraw/

https://youtu.be/GziTQKjjVJA?si=uaZryZ1q8qjlXve2

https://youtu.be/LYZixpVzB3Q?si=VsGDUdlDzpJcFGTg dirty pot

https://youtu.be/Pu0hxKCxeyA?si=rm6lc4yqLpfeT-iE dirty pot

Tree Leaves

There are multiple leaves that can be used for natural dyeing. Birch leaves will create a vibrant yellow if picked in spring. Oak leaves yield ochre and beige colorways.

The leaves from fruit trees like apricot, peach, plum and cherry are also suitable for natural dyeing. The colors created from those leaves will range between shades of yellow and green.

In general, if you pour boiling water over the leaves and let them soak for several days, you might already have enough color extracted to dye with. It is also possible to simmer the leaves for about an hour, let them sit overnight

SEE LEAVES & EFFECTS. for 2022 tests on leaves…

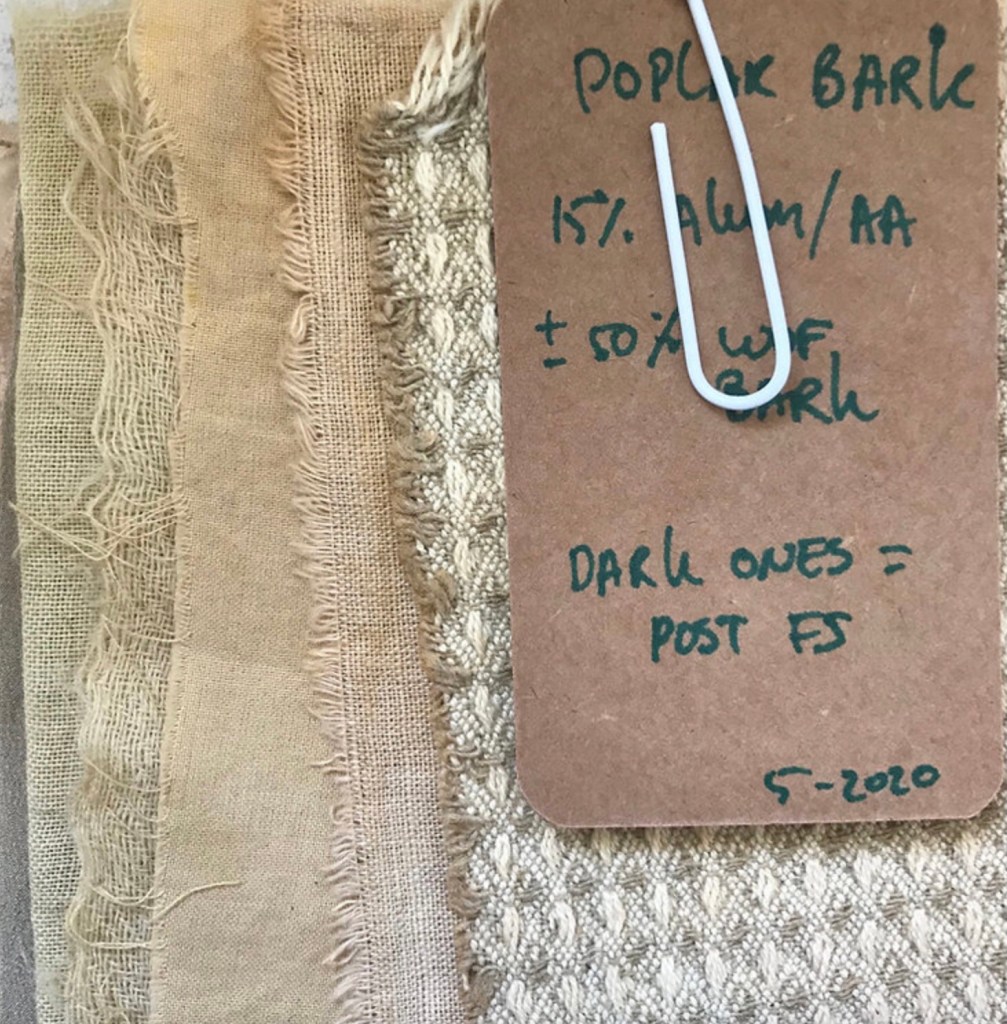

ROOTS/BARKS

Many woody materials will not yield a significant dye color unless a modifier is added. Experimentation is required here. In a small containers place a small amount of the dye liquor, mixing different mordants, and auxiliaries will yield different colors. Some woody products yield colors only under basic conditions, adding soda ash and or baking soda will extract the color desired. Other woody materials will yield color under bizarre situations, as with maple bark. Maple bark will yield a blue dye color, when boiled in stagnant water with large amounts of iron mordant, fermented walnut hulls will yield a purplish color.

You do not have to mordant anything when dyeing with barks, they contain so much tannin that they self-mordant.

FLOWERS:

Flowers are a bit hardier than woody materials. Isoak the flowers overnight, or even for several days, before heating up the dye liquor. I bring the dye bath up to a simmer, 120-180º F, where it remains for thirty minutes. I often add the mordant to the dye bath while the dye materials are still in the pot. I use multiple extractions to extract the color from the dye materials. Otherwise I allow the pot to cool and sit for several days or weeks. I use a potato masher and mash the flowers after they have soaked. This aids in extracting additional dye color from the flower heads.

FRUITS AND VEGETABLES

I use the same method with fruits and vegetables as I do with flowers, however I may run them through a food grinder/processor first, to ensure the greatest amount of color extraction.

yellows

Dandelions

Dyeing with plants that are considered weeds and are available in abundance is always a favorable option. According to the literature [1], dandelions (you can use both the flowers and the leaves) produce clear shades of yellow that can be shifted towards green when modified with iron.

Goldenrod is a very powerful dye plant which creates beautiful bright shades of yellow. You don’t have to use large quantities of it and it is even possible to use the solar dyeing method without any additional heating except for the sunlight. You will get the brightest color results if you use goldenrod when the flowers have just opened.

Sunflower

some sunflowers give non-yellow

ELDERBERRY The bark and the leaves, however, produce beautiful and stable colors. I received a light creamy-beige color from the bark and a yellow from the leaves. However, I have to admit, I absolutely disliked the smell of the bark in the dye bath.

Pine Needles

absolutely beautiful warm yellow. When modifying the yellow yarn with iron afterwards, I received a beautiful green color

Aspen – Aspen/ poplar. is an American plant that is an excellent dye plant. It doesn’t make reds and oranges but rather hot yellows and strong olive greens. Quaking aspen (Populus tremuloides) has the widest distribution of any tree in North America (link) so many people can easily gather it and learn to dye with it. One nice thing about trees as dye plants: it is relatively easy to get enough leaves to fill a dyepot.. and olive greens

Marigold Blossoms

· Place Marigold Blossoms into a plastic bucket and cover them with hot, not boiling, water. A one-gallon bucket or container will work well for this method. Marigolds will yield the greatest color if allowed to soak for an extended periods, upwards of thirty days. Just place the solution in a warm area, such as a sunny window, heat to a simmer every few days to prevent mold from forming.

BROOM – especially when in blossom, used as a resist

GREENS

Nettle is one of the dye plants of which the final color result on the yarn changes depending on the season. It is best used in spring when the shoots are fresh and young. Then, you can receive a beautiful sage green. The dyeing process yields a beige with a green undertone at first which transforms into a green with the use of iron.

PINE NEEDLES – see above

TRY THIS GREEN. You can obtain mossy greens by dyeing with yellow and using modifiers such as copper and iron.

spinach

APPLE DYE COLOURS: Teal blue-green from pink blossoms; yellow-green from leaves.

GREYS

ROSE. When I tried modifying the color with iron, though, it quickly transformed into a beautiful grey color with a green undertone. And, like it is the case with many dye plants, the color results from the rose petals slightly change depending on the time of the year when they are picked. The colors tend to be more vibrant earlier in the season and more muted towards fall.

BROWNS

OTHER COLOURS

BASIL/Purple basil. need to see if fugitive

– magenta – fermented dandelion. root

BLUE -bark /fruit of dogwood

black

can print on heavy iron cotton for black leaves

Suitable Plants for Solar Dyeing

Onion skins : creates yellow/rust

Goldenrod: creates yellow colorway

Tansy: creates yellow colorways

Tea & Coffee

WHAT MAKE A GOOD DYE

One major group of flavonoids are Anthocyanidins and Anthocyanins

These common reds and oranges of nature are the dyes we prefer to avoid. They are fugitive colorants with poor color fastness

Anthoxanthins Anthoxantins are divided into Flavones and Flavonols. These pigments are generally whiter in an acid medium and yellowed in a ph neutral or alkaline medium. This is the reason we add a bit of chalk to the dye bath.

Flavones and flavonols always need a mordant salt like alum to connect themselves permanently to the textile. I only list those most important to dyers. Weld, mullein, onion skins, henna) Apigenin Rhamnetin Quercetin Kaempferol Fisetin (Ch amomile) (Buckthorn bark and berries) (Oak, eucalyptus, onion skins, St. John’s-wort) (Mullein, sage, tea, onion skins) (persimmons, quebracho) Fustin (Fustic) Rhamnazin (Rhamnus bark, Buckthorn berries) Rutin leaf, Sorrel leaf, Morin

Isoflavonoids (Eucalyptus, Buckwheat, Tobacco plants, Prunus, Elderberry Rhubarb roots) (Osage Orange, Old Fustic

Flavans genista tinctoria This group of flavonoids is also very rich in tannins. The tannins assist in fastness of these dyes. In order to ‘catch’ the flavans in these dyes you must mordant the fabric with alum and the dye bath should be heated.

MORDANTS

titanium oxalate

1. Strong reaction to tannin: Titanium oxalate will give you orange shades with tannins and yellow dyes. This is of particular interest to dyers who do botanical prints. Leaves which are full of tannin will come out more orange/yellow than if alum or aluminium acetate was used. strong orange reaction with tannins, and as such it can give beautiful oranges in eco printing,

Titanium oxalate as a Post-mordant

Using titanium as a post-mordant will give bright to medium oranges

– 100 grams of fibre

– 5 to 15 grams of titanium oxalate

1. Dye your fibre in the extract in the usual way. For this method do NOT mordant the fibres first.

2. Dissolve the titanium oxalate in a small container with warm water.

3. Add it to a saucepan with water and then add your fibres.

4. Heat slowly up to 80-90°C for 45 min while regularly stirring the fibre.

5. Let the fibres cool in the saucepan.

6. Rinse once or twice at room temperature

Using titanium as a pre-mordant will give you attractive peachy tones

– 100 grams of fibre

– 5 to 15 grams of titanium oxalate

1. Dissolve the titanium oxalate in a small container with warm water.

2. Add it to a saucepan with water and then add your fibres.

3. Heat slowly up to 80-90°C for 45 min while regularly stirring the fibre.

4. Let the fibres cool in the saucepan.

5. Rinse once or twice at room temperature.

Tin – used mainly when bright shades of red and yellow are wanted for wool and silk. not for cotton.

Mordants are water-soluble chemicals, usually metallic salts, which create a bond between dye and fiber thus increasing the adherence of various dyes to the item being dyed. The actual color one gets from a natural dye depends not only on the source of the dye but also on the mordant, and the item being dyed.

Most mordant recipes also call for the addition of cream of tartar or tartaric acid. Use of this readily available spice is important because it reduces fiber stiffness that can occur because of mordanting. It can also increase brightness.

Table 1. – Mordants most commonly used with natural dyes.

Mordant

Effect

Alum – Brightens the colors obtained from a dye source

Iron/Coppers – Darkens/saddens hues, produces blacks, brown, gray

Copper vitriol – Improves likelihood of obtaining a green hue

Tin – Produces bright colors especially yellows, oranges, reds

Chrome – Highly toxic – should not be used for dyeing at home

CREAM OF TARTER – use on silks when using fe or cu to prevent brittleness

As a single-step mordant, you use aluminium lactate at 5%-10% WOF for cellulose fibers.No need to heat, dissolve the aluminium lactate in hand-warm water and top up with water at room temperature. Leave your fabrics in the mordant for at least 1.5 hours. For a two-step process to create more mellow colors, use tara or oak gall tannin at 10% as first tanning and only then proceed using the aluminium lactate at 5-10% WOF.

Magnesium Sulphate or Epsom Salts is one of my most used and favourite mordants. I find it’s easier to come by than alum in the shops. . It pushes the colours more to purple/brown/pink than the yellows of aluminium. It’s not been mentioned in any workshops or pdfs that I’ve seen, just the results of my own experimentation and research.

Home-made aluminium tri acetate and ferrous sulfate mordant for cotton. The Magic Mordant for cotton. The aluminium triformate react with the yellow flavonoids and green chlorophyl, the ferrous sulfate gives gray and black with tannins, the copper sulfate brings out golden browns.

Important: this process will foam a lot and needs to be done in an oversized bucket or stainless steel dye pot. Never ever use aluminium pots for recipes containing soda ash.

Ingredients:

Alum, soda ash, vinegar, ferrous sulfate, water.

First make aluminium acetate:

- Calculate 20% WOF alum

- Dissolve in HOT water, then add one liter of cold water

- Calculate 150% acetic acid (vinegar 5% which is regular household vinegar) (liquid according to weight) and combine with the alum water.(in metric weight, vinegar is the same in weight as in volume, so if you would need 500 grams of vinegar that’s half a liter) (another way to calculate this is 15cl per 10ogr WOF, so 200 grams of dry fabric will need 30 cl = 300 ml of vinegar for the mordant)

- Calculate 10% WOF soda ash

- Dissolve in hot water in a separate container

- Add the soda ash solution to the alum and vinegar solution, it will bubble violently! Stir and keep stirring until the bubbling stops.

Adding the ferrous sulfate

- Calculate 1.5% WOF ferrous sulfate, dissolve in half a cup of hot water in a dedicated container, make sure there are no bits undissolved.

- Add the ferrous sulfate water to the aluminium acetate and stir well.

- Add more warm (around 50ºC) water to create enough solution for your fabric to float.

BEST RESULTS. —Combining these two in the correct order keeps crisp white backgrounds. If we would mordant with two separate mordants the fabric would get the buff shade of regular ferrous sulfate mordant.

Let your pre-wetted fabric sit in this solution for at least 1.5 hours. Stir well in between.

Remove fabric from the mordant, rinse briefly with clear tap water, squeeze dry very well and continue to the botanical printing stage.

A little tip for cellulose fibers: Linen and cotton take on better colors by pre-treating these fibers, yarns, or fabrics, for one hour in water with soda ash, creating water with a pH 10. Boil for 1 hour. Rinse and dry, then wet again and mordant in the ATF solution. Mordanting process: Keep pre-wetted fibers for 5-8 hours in the ATF mordant. Stir well regularly in the beginning to ensure even coverage. Squeeze your mordanted material so that the liquid goes back to the bucket. Rinse several times before dyeing or printing. Your mordant can be re-used at least three

The best mordants for cotton are always combined mordants that are either alkaline or acidic. Regular alum has very little affinity with cellulose fibers so it will not combine well.

If the bath ratio is too small, the mordant water may not be able to reach all the creases and uneven coverage is the result. I have seen this first hand with stripes and blotchy dye samples.

Post mordanting; To dung or not to dung?

Some will say it is an essential part after mordanting, I personally do not always take the time to do it.

“Dunging” was original done with cow manure in water. The phosphates and minerals in the poop would help remove unattached mordants from the fabric.

Today we dung using chalk or bran, or both. Remember that this is an option, I recommend doing a side by side to check if you feel the work is worth the difference.

The chalk, which is mildly alkaline, neutralizes the acid mordanted fabrics

Chalk Dung Bath

Ingredients:

10 liters of water

50 grams of chalk

How-to

Dissolve the chalk in the water, give it a good stir.

Soak the mordanted fabrics in the chalk water for two minutes.

Squeeze excess water back in the bucket.

Rinse.

Proceed to use or dry.

Bran Dung Bath

Ingredients;

10 liters of water

100 grams of wheat bran

How-to

Soak the wheat bran in the water for about 30 minutes to start enzymic hydrolization.

Soak. the mordanted fabrics in the bran water for 10 minutes.

Squeeze excess water back in the bucket.

Rinse

Proceed to use or dry.

To prevent ‘bleeding’ of your prints make sure your fabric is first fully wetted out, and then wring it until moist to the touch without any dripping. Lay out your fabric on a clean flat surface. Use your hands to smoothen out any creases in the fabric. Lay your leaves with the down part facing the fabric. For eucalyptus there is not really any particular side.

Now take a second pice of cotton that is fully wetted out and wring it the same way as your target piece. Place over your leaves.

This layer of fabric that’s without any mordant will absorb a lot of the yellows releasing. You can simply wash and re-use this cotton again and again. Smoothen this layer out well and place a barrier layer over this.

Take a dowel and roll it strong over this sandwich to release some of the juices in the leaves and smoothen the bundle. Roll the sandwich while pushing the surface. Roll and push. Pull the bundle towards you as you go to release strain on your back. Finish rolling and now tie the bundle using thin sturdy rope or rubber bands. Heat 1.5-2 hours using steam or boiling wat